Let's Learn About Carbon Ceramic Brakes

When we talk about 'Super Technology' and 'Performance' in the automotive world, we mostly focus on engine power and acceleration. But in reality, the most important capability a vehicle must have is the ability to stop. This is where Carbon Ceramic Brake (CCB) technology comes into play. This is a superior technology that is vastly different from standard brakes.

Let's look at what these are, how they work, and why they are so expensive.

What are Carbon Ceramic Brakes?

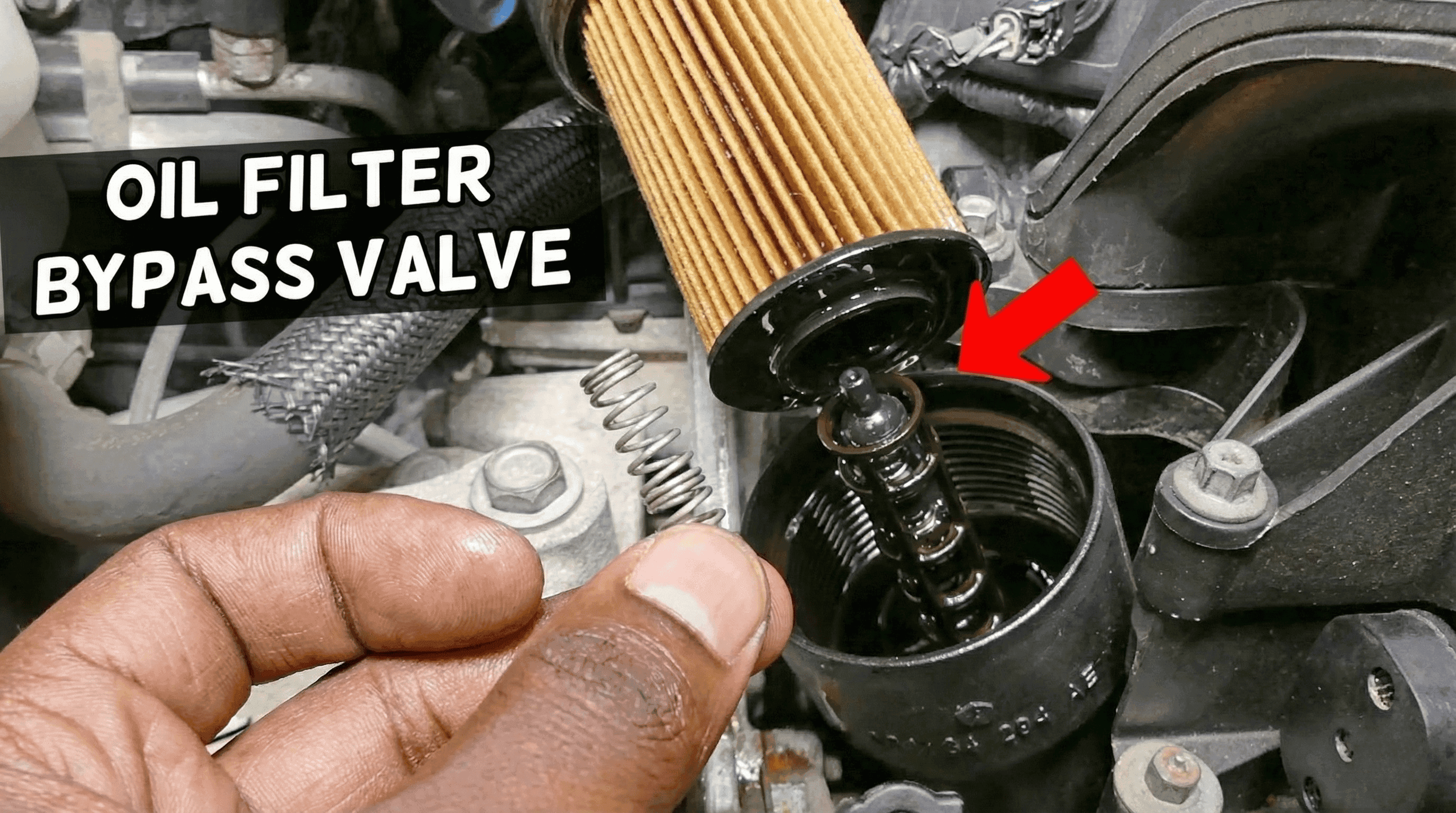

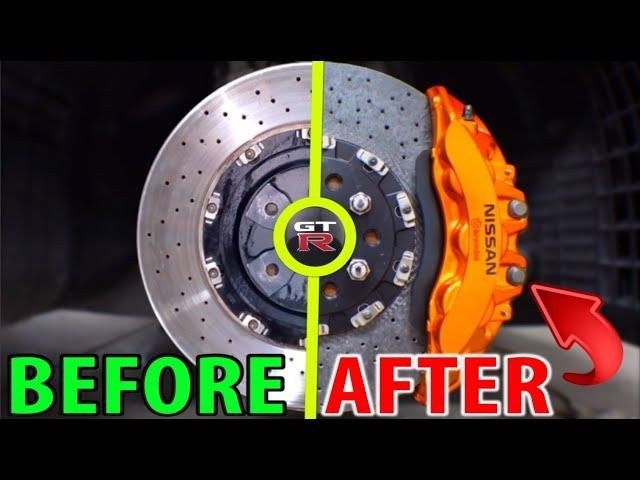

Brake discs in standard vehicles are made of Iron (Cast Iron). However, the discs in Carbon Ceramic Brake systems are manufactured using a mixture of ceramic materials such as Carbon Fibers and Silicon Carbide. The manufacturing process of these discs is very complex. Carbon fibers are mixed with resin and converted into ceramic (Ceramization) under high pressure. This gives the disc extreme hardness and heat resistance.

What are the special advantages of CCB?

There are several key reasons why this technology is mainly used in Supercars and Race Cars.

- Weight Reduction: A CCB disc is about 50% lighter than a standard steel disc. This weight reduction happens in the vehicle's Unsprung Weight (the weight below the shock absorbers). Reducing Unsprung Weight significantly improves the vehicle's handling, suspension performance, and ride comfort.

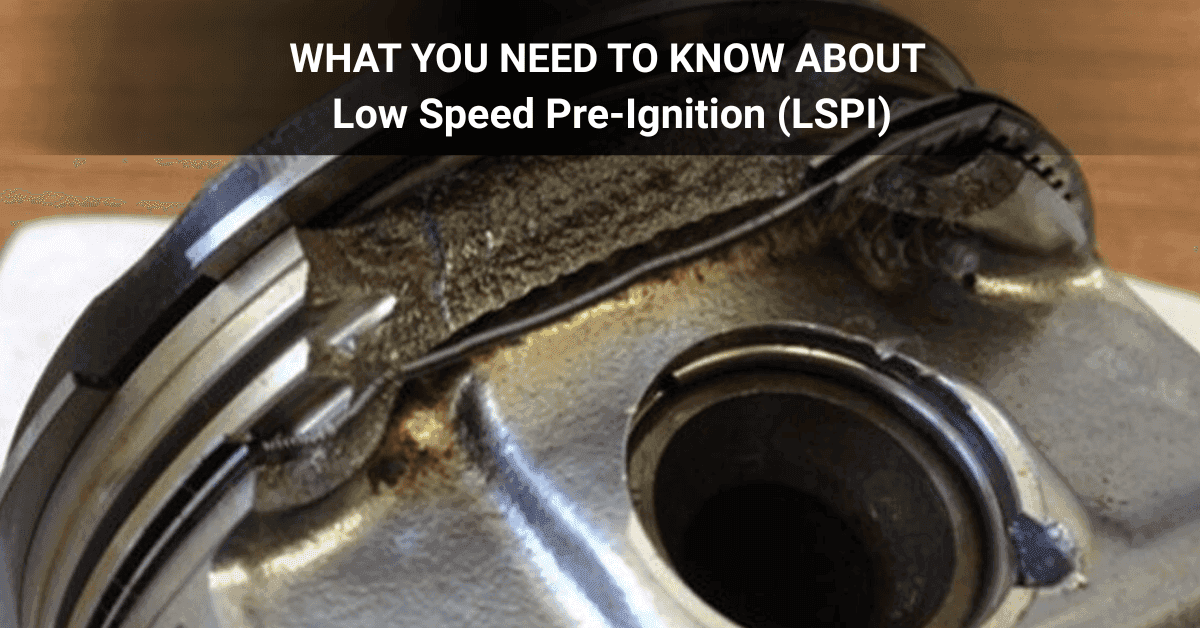

- Heat Resistance and Minimal Fade: When braking hard, friction causes brake discs to heat up excessively. As standard iron discs heat up continuously, their braking performance decreases (this is called Brake Fade). CCB discs can withstand extreme temperatures as high as 1000°C. Since the heat dissipation capability of these discs is extremely high, the risk of performance drop (Fade) is very low, even on a race track.

- Longevity: In normal use (not track driving), CCB discs last about ten times longer than standard iron discs. Sometimes, they can last for the entire lifespan of the vehicle.

Disadvantages and Practical Issues

Although this is superior technology, there are several main problems that prevent it from being used in standard vehicles:

- High Cost: The main issue is the price. Due to the complex manufacturing process, a CCB system costs ten times or more than a standard system. If a disc or caliper is damaged, the repair cost is extremely high.

- Operational Characteristics: CCB discs show their best performance when they are hot. In everyday normal road driving or cold weather, they may not offer the instant and sharp braking response of standard iron discs.

- Noise: Sometimes, especially at low speeds and in cold conditions, there is a tendency for them to make a Squealing Noise.

Reasons for Using Carbon Ceramic Brakes in Racing

CCB systems are essential under racing conditions mainly due to factors like high speed, the need for constant braking, and time.

Thermal Management

In racing, a driver applies brakes very hard within a very short time frame. For example, before turning into a corner from a straight stretch, speed might need to be reduced from 300 km/h to 60 km/h. In this process, the braking system has to convert a massive amount of energy into heat. When iron discs fail to handle this heat and heat up quickly, Brake Fade occurs, and the driver loses control of the vehicle. Since CCB discs can operate without any performance loss even at higher temperatures, Brake Fade can be almost completely avoided. This is extremely important for safety as well as winning in racing.

Mass Reduction Advantage

Every kilogram matters in racing. The weight reduction offered by CCB is a crucial factor. Since CCB discs are 50% lighter than steel discs, this reduction in Unsprung Weight allows the wheels to grip the road surface better. This weight reduction significantly increases steering precision, traction, and cornering speed. These small changes are vital for achieving the fastest Lap Time.

Consistency and Reliability

Racing drivers need to be assured that they will get the exact same braking power at the same spot in the next lap as they did in the previous one. Even when CCB systems get hot, there is no change in their performance, so drivers can use the same Braking Point every time.

Endurance Races

In races that run for hours (Endurance Racing), normal brake discs wear out very quickly and need changing. However, due to the extremely long lifespan and high resistance to wear of CCB discs, it is possible to use the same set of discs throughout the entire race.

Racing is a struggle against time, and Carbon Ceramic Brakes allow drivers to save fractions of a second while maintaining constant safety and confidence. Therefore, although expensive, they have become a mandatory component in super sports cars and racing.